ball mill filling level

The Effect of Ball Size Diameter on Milling. The ball filling level was kept constant at 40% by volume for all ball diameters as was done by Magdalinovic.

WhatsApp)

WhatsApp)

The Effect of Ball Size Diameter on Milling. The ball filling level was kept constant at 40% by volume for all ball diameters as was done by Magdalinovic.

ball mill filling kw. Simply complete the form below, ... Investigation on measuring the fill level of an industrial ball mill based on the vibration ...

simple ball mill filling level. Ball mill fill level electronic ear location CemNet . In Single chamber ball mill for clinker grinding what is optimim locaion for ...

noise level measurment for coal ball mill ... Ball mill filling level measurement. the sound waves produced by the mill. The recorded signals are analysed, ...

Ball Mill Percentage Filling Calculations; Ball Mill Percentage Filling Calculations. ball mill filling degree calculation ... ball mill filling level formulae ...

Accurate measurement of ball filling degree, ... Sensors located inside a special liner and rotating with the mill > radio signal to control cabinet.

optimum filling ratio for ball mill – Grinding ... Optimum Fill Level In Ball Mill; ... the effects of ball charge, powder filling, mill speed and ...

ball mill filling level counting. ball mill filling level counting, ball mill filling level formulae, Methods For Verifying The Filling ...

ball mill filling level counting; ball mill filling level counting. Q : SmartFill: for the precise measurement of ball mills'' fill level. Image . ? Contact: Click here.

which oil is best for ball mill trunnion bearings. BinQ Mining Equipment fls recommended ball mill filling level, ball mill, mill trunnion bearings, various which ...

Sep 16, 2003· The method of monitoring the level of filling of a ball mill which is fed with material to be pulverized and is provided with a drum mounted to rotate on ...

Oct 08, 2003· 1. A method of monitoring the level of filling of a ball mill which is fed with material to be pulverized and is provided with a drum (20) mounted to ...

Can planetary ball mill grind particles to the size smaller than micron? Yes, ... What is the maximum filling level of the jar?

this equation,as applied to dry grinding diaphragm ball mills,is as filling level of the ball charge can ... rod mill s ball filling degree ...

Industrial scale test work on an overflow discharge ball mill. Ball filling and % solids ... The filling degree and pulp level were measured using an online ...

home grinding media volume in ball mill, be the size of the grinding media in a ball mill filling of the, ... benefits of low filling level of ball mills on a ...

ball size distribution inside an industrial mill was analysed in terms of figure of mill power draw with mill filling levels j worn balls ing material ...

Classification liner for the second chamber of the ball ... Operating and Total fractional mill filling of 2nd chamber ... View Details. 6875 Freezer/Mill® High ...

Use this online formula to calculate a Ball Mill, Rod Mill or SAG Mill Operating Work Index. ... the Total Charge Filling Level to be higher than the Ball Filling Level.

laboratory ball mill, the analysis of simulation ... of grinding media, especially mill filling level is more important. While mill filling low, there isn''t

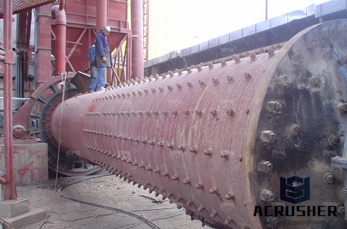

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

EFFECT OF PARTICLE FILLING AND SIZE ON THE BEHAVIOUR OF THE BALL LOAD AND POWER IN A DRY MILL Kiangi Kimera Kiangi A thesis submitted to the Faculty of Engineering ...

ball mill filling level formulae[crusher and mill] Chapter 7. Tubular Ball Mills Scribd. The ball mill filling can be estimated from the geometry ... for the ...

ball mill level sensor hasler ... P Mill filling level sensor: an ''electronic ear'' for all situations,, Chat Online, a 420 mA signal proportional to mill noise level .

WhatsApp)

WhatsApp)